Boilers are indispensable equipment in many industries, from power generation to manufacturing and heating. Boilers are essential heat exchange devices used across various industries to generate steam or hot water by converting energy from a fuel source into heat. This heat is then transferred to a working fluid to produce steam, which can be used for various purposes, including heating, power generation, and industrial processes. Boilers play a crucial role in industries such as power generation, manufacturing, food processing, chemical production, and more, serving as the backbone of many industrial processes.

In this blog, we will explore the importance of boiler mountings, their key components, and how they contribute to safe and efficient boiler operation.

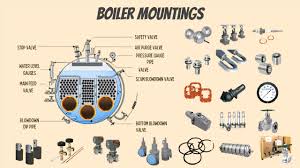

What are Boiler Mountings?

Boiler mountings are the collection of essential fittings and accessories that are mounted on the boiler to ensure its safe, efficient, and reliable operation. These components are designed to control various aspects of the boiler’s performance, such as pressure, water level, temperature, and safety. Boiler mountings are critical for regulating the boiler’s operation and preventing accidents, which is why their proper installation and maintenance are paramount.

Why are Boiler Mountings Important?

Boiler mountings are essential for several reasons:

- Safety: Boilers operate at high pressures and temperatures, making them inherently dangerous if not properly controlled. Mountings ensure that the system operates safely, preventing accidents such as explosions or pressure ruptures.

- Efficiency: Properly functioning mountings help in regulating the steam and water levels, fuel consumption, and overall heat efficiency of the boiler.

- Longevity: Well-maintained mountings can extend the life of the boiler by preventing malfunctions, reducing wear and tear, and improving overall system performance.

Now, let’s dive deeper into the key boiler mountings that are critical for safe and efficient boiler operation.

Overview of Different Types of Boiler Mountings

- Pressure Gauge

The pressure gauge is one of the most crucial mountings on a boiler. It indicates the internal pressure of the steam inside the boiler. Monitoring the pressure helps operators ensure that the system is operating within safe limits. If the pressure exceeds the safe range, it could result in dangerous situations, such as boiler explosions. - Water Level Indicator

The water level indicator provides a visual indication of the water level inside the boiler. It is essential to monitor this level regularly, as the boiler should always have enough water to prevent overheating or dry running of the boiler. An inadequate water level could result in overheating of the boiler tubes, causing them to crack or even burst. - Safety Valve

The safety valve is a crucial safety component that prevents over-pressurization of the boiler. When the pressure inside the boiler exceeds a preset limit, the safety valve automatically opens to release excess steam and reduce the pressure. This prevents the boiler from potentially rupturing under excessive pressure. - Steam Stop Valve

The steam stop valve is used to control the flow of steam from the boiler to the desired location, such as a turbine or heat exchanger. It is typically installed on the steam outlet pipe. The valve allows operators to stop or regulate the flow of steam, ensuring smooth operation. - Blow-off Valve

The blow-off valve is used to remove impurities, sludge, and scale from the bottom of the boiler. Over time, these deposits accumulate, and if left untreated, they can affect the boiler’s efficiency and lifespan. The blow-off valve enables operators to flush out these impurities by allowing water to be expelled from the boiler. - Feed Check Valve

The feed check valve regulates the flow of feedwater into the boiler. It ensures that water is continuously supplied to the boiler at a controlled rate. The valve prevents the backflow of steam or water into the feedwater pipe, ensuring that the boiler receives a steady supply of water for steam generation. - Gauge Glass

Similar to the water level indicator, the gauge glass provides a transparent visual reference of the water level inside the boiler. However, the gauge glass allows for a more precise and clear view of the water level, which is especially useful during inspection and monitoring. - Thermometer

The thermometer measures the temperature of the water or steam inside the boiler. Monitoring the temperature ensures that the boiler is operating at optimal conditions and helps prevent overheating, which could cause damage to the system. - Manhole and Handhole

Manholes and handholes are openings on the boiler’s shell used for maintenance and inspection. Manholes are large enough for a person to enter and inspect the interior of the boiler, while handholes are smaller and used for cleaning and inspecting the boiler’s components. These access points allow technicians to safely perform maintenance tasks without having to disassemble the entire unit. - Air Vent Valve

The air vent valve is used to release any air trapped inside the boiler during the filling process. Air can accumulate when the boiler is being filled with water, and if not vented, it could affect the system’s efficiency or even damage certain components. The air vent valve ensures that only water enters the boiler, improving the overall operation.

Boiler Mountings vs. Boiler Accessories

It is important to note the distinction between boiler mountings and boiler accessories. While mountings are critical components that are directly attached to the boiler for safe and efficient operation, boiler accessories are additional devices that support or enhance the boiler’s functionality, such as economizers, superheaters, and air preheaters. Accessories help improve efficiency but are not directly involved in the boiler’s operation.

Maintaining Boiler Mountings

To ensure your boiler operates efficiently and safely, it is crucial to maintain the boiler mountings regularly. Some of the key maintenance practices include:

- Routine Inspections: Regularly check the condition of all mountings, especially the pressure gauge, safety valve, and water level indicator.

- Cleaning: Periodically clean the blow-off valve and check for any sludge or debris buildup in the system.

- Testing: Conduct tests to ensure that all safety devices, such as the safety valve and pressure gauge, are working correctly.

- Replacement of Worn Parts: Replace any worn-out or faulty components to prevent failure and ensure continuous safe operation.

Conclusion

At Steamax Energy India, we recognize the importance of having the right boiler mountings for safe and efficient boiler operation. Properly functioning mountings are essential for the smooth performance of any boiler system. By understanding the role of each mounting, operators can ensure that the system runs at its optimal performance, enhancing safety and longevity.

If you need assistance with boiler mounting installation, maintenance, or are looking to optimize your current boiler system, Steamax Energy India is here to help. Our team of experts is always available to provide guidance, support, and solutions tailored to your specific needs.