What is Boiler in Power Plant and What is Boiler Problem ?

Steam Boiler Manufacturers

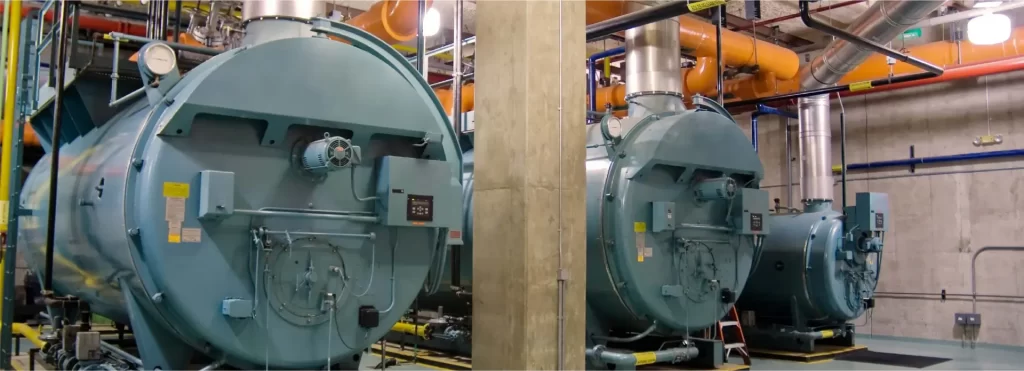

A boiler in a power plant is a large vessel or system designed to convert water into steam by applying heat energy generated from burning fuel (such as coal, gas, or oil). This steam, at high pressure and temperature, is then used to drive turbines connected to generators, ultimately producing electricity. Boilers are essential to the thermal power generation process as they supply the steam that drives the turbine machinery.

Main Components of a Power Plant Boiler

- Furnace: Burns fuel to generate heat.

- Drum: Holds water and separates steam from water.

- Superheater: Increases steam temperature beyond its saturation point.

- Economizer: Preheats the water before it enters the boiler.

- Air Preheater: Warms up the air used for combustion, increasing boiler efficiency.

Common Boiler Problems in Power Plants

Boiler issues can disrupt the power generation process, reduce efficiency, and, in severe cases, cause safety hazards. Key boiler problems include:

Scaling and Fouling:

- Minerals like calcium and magnesium in water form scale deposits on boiler tubes.

- Scale reduces heat transfer efficiency, leading to overheating, reduced efficiency, and potential tube damage.

Corrosion:

- Oxygen, carbon dioxide, and other impurities in the feed water can cause corrosion of boiler parts.

- Corrosion weakens the boiler structure and can lead to leaks or structural failure.

Leakage:

- Boiler tubes, seals, or joints can develop leaks due to high pressure, corrosion, or material fatigue.

- Leaks lead to loss of water and steam, reducing boiler efficiency and potentially causing downtime.

Thermal Fatigue and Creep:

- Repeated heating and cooling cycles cause materials to weaken over time, leading to cracks and material deformation.

- Creep occurs when materials are exposed to high temperatures and stress over time, causing them to gradually deform.

Low Water Conditions:

- Insufficient water levels can cause overheating and tube damage.

- This can happen due to improper monitoring, malfunctioning feedwater pumps, or leaks.

Combustion Issues:

- Poor combustion efficiency can lead to incomplete fuel burning, producing smoke, soot, and other pollutants.

- This reduces energy efficiency and increases emissions, affecting environmental compliance.

Prevention and Maintenance

- Routine inspections, water treatment, timely repairs, and efficient control systems can minimize these problems, enhance boiler efficiency, and extend boiler life in a power plant.

About Steamax Energy India:

Steamax Energy India is a leading manufacturer of Steam Boilers, Thermal Fluid Heaters, Hot air generators, Steam Generator, Oil & Gas Fired Steam Boilers, Hot Water Generators, Coal Fired Steam Boiler, Steam Boiler Plant, Industrial Boiler Tank, Electric Steam Boiler, Oil Gas Fired Hot Air Generator, Wood Fire Hot Air Generator, Non-IBR Wood Fired Steam Boiler.

For any further queries, please let us know! we’ll be happy to assist you with any questions or provide additional information you may need. Contact us@ 07053901803