Industrial Boilers are among the most critical thermal equipment in various industries and heating systems. A wide variety of boilers are available in the market, each designed to meet specific requirements based on the system’s design, capacity, fuel type, and application. They operate by transforming water into steam or hot water through the use of thermal energy. Boilers are manufactured in various types based on different needs and operational conditions, each with its own advantages and specifications. As a leading Steam Boiler Manufacturer, Steamax Energy India understands the importance of choosing the right boiler for different industries, ensuring maximum efficiency, safety, and longevity.

Also Read Us: Understanding Boiler Mountings: Important Parts for Safe and Efficient Boiler Use

In this blog, we’ll explore the different types of boilers, their classifications, and how choosing the right boiler type can enhance energy efficiency and productivity in various sectors.

What is a Boiler?

A boiler is a closed vessel or container that is used to heat water or other fluids to generate steam or hot water. The steam or hot water produced is typically used for heating, power generation, or other industrial processes. Boilers are crucial components in many industries, ranging from power plants and manufacturing units to residential and commercial heating systems. Boilers are classified into various types based on their design and application, each with its own unique features and advantages.

Boiler Classification: An Overview

Boilers can be classified based on different criteria such as:

- Design and Construction

- Fuel Type

- Application

- Pressure and Temperature

- Working Principle

Let’s take a closer look at these classifications:

1. Classification Based on Design and Construction

Boilers can be broadly classified into two categories based on their construction design:

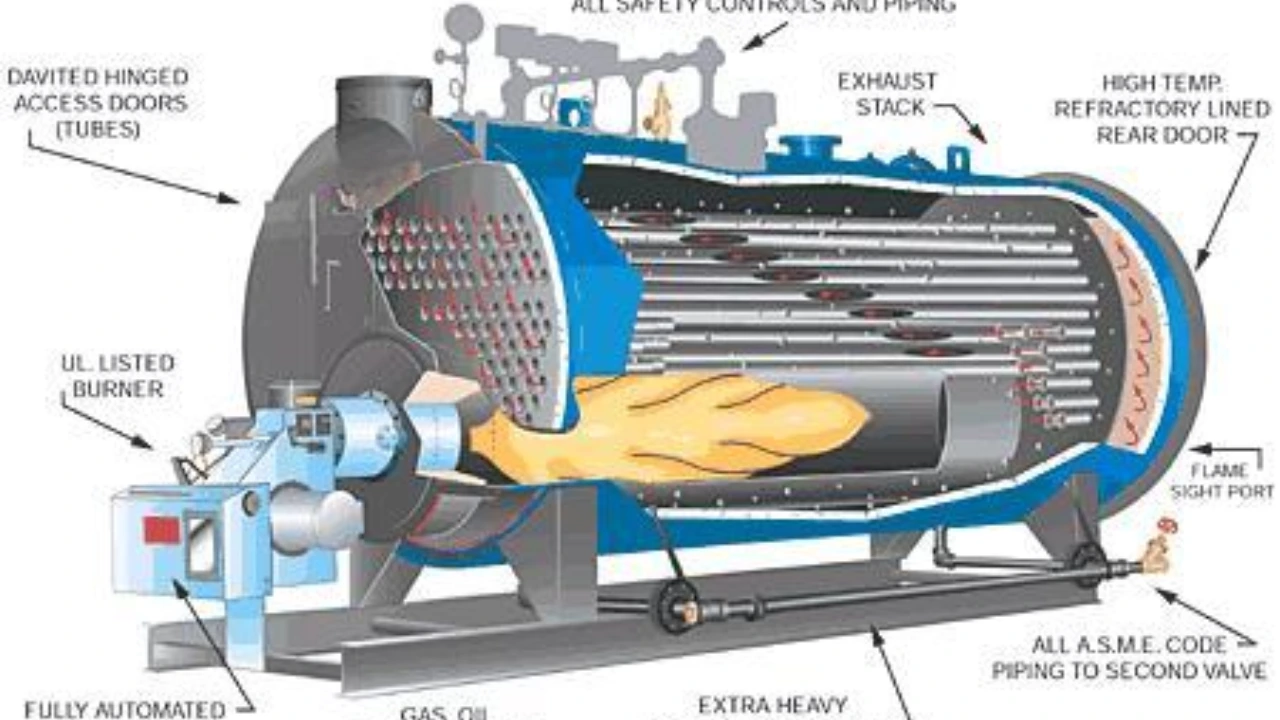

- Fire-Tube Boilers: In this type of boiler, the hot gases produced by burning fuel pass through tubes surrounded by water. The heat from the gases transfers to the water, which then turns into steam. Fire-tube boilers are typically used in small to medium-scale applications and are known for their compact design and relatively low pressure operations.

- Water-Tube Boilers: In water-tube boilers, water circulates inside the tubes, and hot gases pass over the outside of the tubes. This design is suitable for high-pressure and high-temperature applications, making it ideal for large-scale industries that need higher efficiency. Water-tube boilers are commonly used in power plants and large manufacturing plants.

2. Classification Based on Fuel Type

Boilers can also be classified according to the fuel they use. The main fuel types include:

- Coal Boilers: These are traditional boilers that burn coal to produce heat and steam. Coal boilers are more commonly found in industries that have access to coal and require high levels of heat generation.

- Oil Boilers: Oil-fired boilers burn fuel oil to produce heat. These are typically used in places where oil is the preferred or more readily available fuel.

- Gas Boilers: These boilers use natural gas or liquefied petroleum gas (LPG) to generate steam. Gas boilers are increasingly popular due to their high efficiency, low emissions, and ease of operation.

- Electric Boilers: Electric boilers use electricity to heat water or produce steam. These are ideal for smaller installations or locations where access to conventional fuels is limited.

- Biomass Boilers: Biomass boilers use organic materials such as wood pellets, agricultural waste, or other biodegradable materials to produce steam. Biomass boilers are eco-friendly and increasingly popular in green energy applications.

3. Classification Based on Application

Boilers can be classified based on the industry and application where they are used. For example:

- Industrial Boilers: These are large-scale boilers designed for heavy-duty industrial applications such as power plants, paper mills, chemical factories, and steel plants.

- Residential Boilers: These are smaller, compact boilers designed for home heating systems and hot water production.

- Commercial Boilers: These boilers are used in office buildings, hotels, hospitals, and schools for space heating and hot water production.

4. Classification Based on Pressure and Temperature

Boilers are also categorized based on the pressure and temperature of steam produced:

- Low-Pressure Boilers: These boilers typically operate at pressures less than 300 psi. They are used in applications that require low-temperature steam, such as residential and light commercial heating.

- High-Pressure Boilers: These operate at pressures above 300 psi and are used in applications requiring higher temperatures and more powerful steam production, such as in large-scale power plants.

Types of Boilers Based on Specific Applications

Boilers vary in design and function depending on their application. Below are some of the most commonly used types of boilers in various industries.

1. Fire-Tube Boilers:

They are one of the most common types of boilers. In this type, hot combustion gases pass through tubes and heat the surrounding water, turning it into hot water or steam. Fire tube boilers are widely used Due to their simple design and affordable price. Fire-tube boilers are one of the oldest types of boilers and are widely used in industries that require low to medium pressure steam. These are efficient, cost-effective boilers and are suitable for small industries or residential heating systems.

2. Water-Tube Boilers:

Water-tube boilers are designed for high-pressure operations and are ideal for large-scale industries. These are used in power plants, refineries, and manufacturing plants where high steam production is essential. In this type of boiler, water circulates inside the tubes, and hot gases pass around them. These boilers are used to produce high-pressure steam, as water and steam flow through the tubes.

3. Electric Boilers:

Electric boilers are popular in areas where conventional fuels like gas, coal, or oil are not easily accessible. They are known for their simple operation, compact design, and high efficiency. Electric boilers are used in commercial establishments, schools, and residential settings, providing an eco-friendly solution to heating requirements.

4. Biomass Boilers:

Biomass boilers are the future of green energy solutions, as they utilize renewable and environmentally friendly fuel sources. These boilers burn wood chips, pellets, or agricultural waste to produce steam and are widely used in the textile, food, and chemical industries. Biomass-fired boilers are a type of heating system that utilizes organic materials, such as wood pellets or agricultural residues, as fuel. This machine converts biomass and industrial waste into thermal energy. In these boilers, biomass undergoes combustion to produce heat, which is then used to generate steam or hot water for heating purposes.

5. Oil-Fired Boilers

The last boiler type is an oil-fired boiler. Oil-fired boilers are heating systems that utilize oil as their primary fuel source, used to generate steam by heating water using oil. These boilers are often used in areas with limited natural gas supply, and they are commonly found in industrial settings that require high levels of steam output for their operations.

Why Choose Steamax Energy India for Your Boiler Needs?

As a trusted Steam Boiler Manufacturer, Steamax Energy is committed to providing high-quality, reliable, and efficient boilers for a wide range of applications. We specialize in designing and manufacturing steam boilers that are built to last and perform under the most demanding conditions. With years of experience and a deep understanding of the industry, we offer:

- Custom-built boilers to suit specific needs

- High-efficiency systems that reduce energy consumption

- Expert guidance in choosing the right boiler for your application

- Timely and cost-effective solutions

At Steamax Energy India, we pride ourselves on delivering steam boilers that meet international standards, ensuring quality, safety, and sustainability. Whether you are looking for fire-tube boilers, water-tube boilers, or customized solutions, we are your go-to partner in ensuring smooth and uninterrupted operations.

Conclusion

Understanding the different types of boilers and their classifications is crucial when selecting the right equipment for your business or home. With a wide range of boilers available, from fire-tube boilers to biomass boilers, choosing the appropriate one will ensure that your system runs efficiently, cost-effectively, and sustainably. As industries evolve, the dynamic nature of boiler technology becomes apparent, highlighting the pivotal role these systems play in shaping efficient, sustainable, and innovative industrial practices. As a leading Steam Boiler Manufacturer, Steamax Energy India offers the expertise, technology, and customer support needed to help you make the right choice for your specific requirements.