Steam Boiler Manufacturer

Steamax Energy India is one of the best manufacturers and suppliers of steam boiler manufacturer in India. We are working as industrial steam boiler manufacturers and suppliers in India for the last 9+ years with the help of 12+ skilled engineers and 5000+ satisfied clients in 400+ industries served. A steam boiler is a vital industrial device that generates steam by heating water, commonly used in power generation, manufacturing, and processing industries. It ensures efficient energy transfer and optimal performance. Steam boilers come in various types, including fire tube and water tube, designed for specific applications.

Applications:

- Engineering Industry

- Oil and gas industry

- Chemical Industry

Features:

- Low maintenance

- High efficiency

- Low running costs with a simple installation process.

Steam Bolier We Serve in

- Food & vegetable Processing Industry

- Ply Wood

- Plastic Processing, Heating and Drying

- Paddy par Boiling Plants

- Chemical Industry

- Pharmaceuticals and Medicine Manufacturing

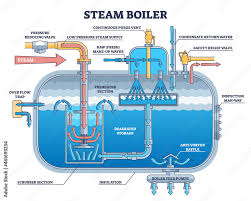

Steam Boiler Diagram

Our Products

Fill The Form

Established in 2014, Steamax Energy India is a leading steam boiler manufacturer and supplier in Ghaziabad, Uttar Pradesh, India. With over 10 years of experience, the boiler companies in India specialize in IBR-compliant steam boilers that serve industries, including engineering, oil and gas, and chemicals.

Key Offerings

- High Efficiency: Steamax boilers are designed for optimal performance, achieving efficiencies of up to 81%.

- Versatile Applications: The products cater to sectors such as food processing, pharmaceuticals, and textiles.

- Low Maintenance: Their designs ensure minimal upkeep while maintaining high operational reliability.

Technical Specification

| Specification | Value |

|---|---|

| Boiler Make | Steamax |

| Year of Manufacture | 2024 |

| Maximum Continuous Rating (MCR) | 10 TPH (F&A 100°C) |

| Rated Working Pressure | 10.54 kg/cm²(g) |

| Type of Boiler | 3 Pass Fire Tube |

| Fuel Fired | Biomass / Coal / Oil |

| Steam Generation Pressure | 7 kg/cm²(g) - Saturated |

| Feed Water Temperature | 60 °C |

| Enthalpy of Steam | 660 kCal/kg |

| GCV of Fuel (Oil) | 10200 kCal/kg |

| Boiler Efficiency | 81 % |

| Operating Range (Capacity) | 50 Kg/hr to 850 Kg/hr |

| Multi-fuel Options | HSD/Natural Gas/LPG/Biomass |

| Flue Gas Temperature (Tf) | 220 °C |

| Ambient Temperature (Ta) | 27 °C |

| Percentage of Oxygen in Flue Gas | 7% |

| Percentage of CO2 in Flue Gas | 11% |

A Steam boiler is a type of steam generator from a soft water heating machinery system that uses fuel solid waste, dry wood, coal, diesel oil, Gas (LPG / natural gas), and Rice Husk As it is a heating energy source to generate steam, electric source is required to operate or control the panel, Water Feed Pump, Pressure Control Switch, Water level controller, etc.

We are leading manufacturers of steam generator boiler, steam generator turbines, bathroom steam generator, heat recovery steam generator, steam boiler price, steam boiler industry, steam boiler drum, and steam generator for bathrooms that use electricity as their primary energy source to produce steam. Wood-fired steam generators, also known as wood-fired 500 kg steam boilers, can then be used for applications. We also offer boilers for dry cleaners, steam boilers for breweries, and solutions tailored to specialized needs, such as autoclave boilers and pellet steam boilers. As a top electric steam boiler manufacturer in India. whether you need a 500 kg/hr steam boiler 100 kg/hr steam boiler, or commercial & industrial steam generators, trust Steamax Energy India for reliable steam solutions.

What is a steam boiler?

A steam boiler is a device used to create steam by applying heat energy to water, commonly used in industrial applications for heating and power generation.

What types of steam boilers do you offer?

Steamax Energy India offers a range of steam boilers including fire-tube, water-tube, and packaged boilers designed for different industrial needs.

What industries use your steam boilers?

Our steam boilers are widely used in industries like food processing, chemical plants, pharmaceuticals, and textile manufacturing.

Are your steam boilers energy efficient?

Yes, Steamax boilers are designed for high efficiency, reducing fuel consumption and operational costs.

What fuel types are compatible with your boilers?

We provide boilers that can operate on various fuels like natural gas, diesel, coal, and biomass.

Do you offer after-sales service?

Yes, we provide comprehensive after-sales support, including maintenance, repair, and spare parts.

Can I customize a boiler for my specific needs?

Absolutely, Steamax Energy India offers customized solutions to meet specific industry requirements.

What is the average lifespan of your steam boilers?

With proper maintenance, our boilers typically last 15 to 20 years.