At Steamax Energy India, we understand the crucial role that steam boilers play in various industries, from power generation to manufacturing and process heating. Boilers are essential components for producing steam, which is used to power machinery, generate electricity, and support heating systems. In this post, we will explore the key elements of a steam boiler diagram, its components, and how it functions.

What is a Steam Boiler?

A steam boiler is a closed vessel that heats water to generate steam, which is then utilized for various industrial applications. Boilers can operate on different fuels, including natural gas, coal, oil, or biomass. The generated steam can be used in steam engines, turbines for electricity generation, or for heating and powering industrial equipment.

Importance of Understanding a Steam Boiler Diagram

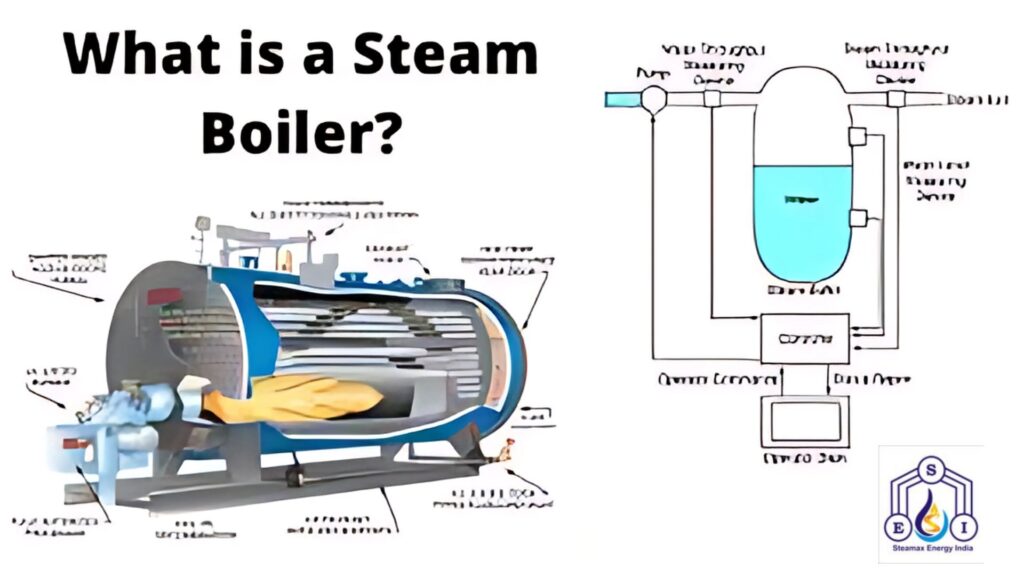

A steam boiler diagram is a simplified representation of the boiler system, showcasing how each component interacts within the system. Understanding the diagram is essential for engineers, operators, and maintenance personnel as it helps with troubleshooting, maintenance, and optimizing the performance of the system. The diagram also aids in ensuring that safety protocols are followed and that the boiler operates efficiently.

Key Components of a Steam Boiler Diagram

To truly understand a steam boiler diagram, it’s crucial to first look at the main components involved. Below are the primary elements you will find in a typical steam boiler system:

- Fuel Supply System: This is where the fuel (gas, oil, coal, or biomass) enters the boiler. The fuel supply system ensures that the fuel is delivered to the combustion chamber in a controlled and efficient manner. The system includes fuel storage, feed lines, and burners.

- Burner: The burner is where the fuel is burned to generate heat. The combustion process creates the necessary energy to heat the water within the boiler. The burner is typically located at the bottom of the boiler, where it is designed to provide a controlled flame for optimal combustion.

- Combustion Chamber: The combustion chamber is where the fuel is burned, and the heat produced is transferred to the water. This heat raises the temperature of the water, turning it into steam. The combustion chamber must be designed to withstand high temperatures and contain the intense heat generated during combustion.

- Heat Exchanger (or Steam Drum): The heat exchanger, or steam drum, transfers the heat from the combustion gases to the water. It is designed with tubes or coils through which water passes. As the water absorbs heat, it starts to evaporate, producing steam.

- Water Circulation System: The water circulation system is responsible for moving water through the boiler. This system ensures that water enters the boiler at a controlled rate and is evenly distributed through the heating elements. It also carries away any impurities or scale that can build up over time.

- Superheater: In many boilers, a superheater is used to raise the temperature of the steam beyond its saturation point. This is important because superheated steam has higher energy content and is more efficient in driving turbines or other machinery.

- Steam Outlet: Once the steam reaches the required pressure and temperature, it exits the boiler via the steam outlet. This steam can then be used for power generation, heating, or other industrial applications.

- Pressure Relief Valve: Safety is paramount when dealing with high-pressure steam systems. The pressure relief valve automatically opens when the pressure inside the boiler exceeds a preset limit. This prevents catastrophic failure due to excessive pressure build-up.

- Water Level Indicator: The water level indicator helps operators monitor the amount of water inside the boiler. If the water level is too low, it can cause the boiler to overheat and even fail. If the level is too high, it can lead to flooding and reduce the steam output.

- Blowdown Valve: Over time, impurities and scale can build up in the boiler water. The blowdown valve helps remove these impurities to maintain the water quality and prevent damage to the boiler components.

How the Steam Boiler Works

The steam boiler works by following a straightforward cycle. First, fuel is fed into the burner and ignited. The combustion process generates heat, which is transferred to the water inside the boiler. The water absorbs the heat and begins to vaporize into steam. This steam rises through the boiler’s heat exchanger and out through the steam outlet to be used in industrial processes.

The entire process requires constant monitoring and control to ensure the boiler runs safely and efficiently. Operators use the steam boiler diagram to understand the flow of fuel, water, and steam, making it easier to identify issues and improve system performance.

Common Applications of Steam Boilers

Steam boilers are used across multiple industries due to their versatility and efficiency. Some common applications include:

- Power Generation: Steam turbines powered by boilers generate electricity in power plants.

- Manufacturing: Boilers are used in factories to provide steam for heating, drying, and powering machinery.

- Textile Industry: Steam is used to process textiles and dye fabrics.

- Food and Beverage Processing: Steam is used for cooking, sterilizing, and pasteurizing food products.

- District Heating: In some areas, boilers generate steam to provide heat to buildings or industrial facilities through district heating systems.

Conclusion

A steam boiler diagram is a powerful tool that helps operators and engineers understand the structure and functionality of a boiler system. It simplifies complex systems and ensures efficient operation and maintenance. At Steamax Energy India, we believe that a deep understanding of the boiler’s components and how they interact within the system is crucial for maximizing efficiency and minimizing downtime.

If you are looking for reliable and high-performance steam boilers for your industrial needs, Steamax Energy India offers a range of products designed to meet the demands of various industries. Our expert team is available to guide you through the process, from choosing the right boiler to installation and maintenance.