Trusted Industrial Steam Boiler Manufacturer in India

An Industrial Steam Boiler is a critical piece of equipment used to produce steam for various industrial processes. Boilers generate steam by heating water, which is then used in processes like heating, sterilization, drying, power generation, and mechanical work in a wide range of industries such as power plants, chemical plants, food processing, and manufacturing.

A High-Pressure Steam Boiler is an industrial boiler designed to generate steam at high pressures, typically above 15 psi, often reaching pressures of 300 psi or more. This high-pressure steam is used for various industrial applications where substantial heat or steam energy is required.

Uses of High-Pressure Steam Boilers:

- Power Generation: High-pressure steam is used in turbines to generate electricity in power plants.

- Industrial Processes: Essential in industries like chemical, food processing, pharmaceuticals, and oil refineries for heating, sterilization, and other heat-based processes.

- Heating and Sanitation: Provides heating for buildings or is used in sanitizing equipment, especially in hospitals and food production.

- Mechanical Drive: In mechanical applications, such as driving steam engines and heavy machinery.

Working Principle of High-Pressure Steam Boilers:

High-pressure steam boilers operate on the principle of heat transfer. Here’s a breakdown of the process:

- Fuel Combustion: Fuel (like coal, natural gas, oil, or biomass) is burned in the combustion chamber, generating heat.

- Water Heating: This heat is transferred to water contained within the boiler. As water absorbs heat, it turns into steam.

- High-Pressure Steam Generation: The steam is pressurized as it accumulates, reaching high temperatures and pressure due to the confined space of the boiler.

- Steam Release: The high-pressure steam is directed through pipes to where it’s needed, such as turbines or industrial machinery.

Features of High-Pressure Steam Boilers:

- High Efficiency: Built for optimized fuel-to-steam efficiency, conserving fuel and reducing operational costs.

- Durability: Constructed with robust materials like alloy steel to withstand high temperatures and pressures.

- Safety Controls: Equipped with safety valves, pressure gauges, and regulators to ensure safe operation under high pressures.

- Compact Design: Many models have a compact design, allowing them to fit within limited spaces while generating high-pressure steam.

- Automated Controls: Advanced systems use automation to regulate temperature, pressure, and fuel input for consistent steam output.

- Heat Exchangers: Built-in heat exchangers improve heat transfer and efficiency.

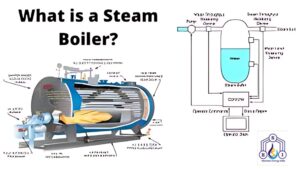

Diagram Explanation (Description):

- Combustion Chamber: Located at the base of the boiler, where fuel is burned to produce heat.

- Heat Exchanger Tubes: Where water passes and absorbs heat from the combustion gases.

- Water and Steam Drum: Stores water and generates steam as it heats.

- Steam Outlet Valve: Releases high-pressure steam for use in external applications.

- Safety Valve: Prevents pressure build-up by releasing excess steam.

I recommend a line diagram showing each of these components with labeled arrows to indicate the flow of water, steam, and heat for clarity.

About Steamax Energy India:

Steamax Energy India is a leading manufacturer of Steam Boilers, Thermal Fluid Heaters, Hot air generators, Steam Generator, Oil & Gas Fired Steam Boilers, Hot Water Generators, Coal Fired Steam Boiler, Steam Boiler Plant, Industrial Boiler Tank, Electric Steam Boiler, Oil Gas Fired Hot Air Generator, Wood Fire Hot Air Generator, Non-IBR Wood Fired Steam Boiler.

For any further queries, please let us know! we’ll be happy to assist you with any questions or provide additional information you may need. Contact us@ 07053901803